MAJOR HEAT TREATMENT PROCESSES FOR CORUNDUM

The oldest and most common gemstone enhancement method is the heat treatment. Heat treatment of gemstones is done to enhance their appearance. Heat treatment may change the appearance of varieties of corundum due to several reasons. To obtain the optimum results different heat treatment processes are used for different varieties. In this article I have briefly explained major heat treatment processes used for corundum treatments.

A. Process No. 1: Removal of silk

Treatment conditions: Heat to between 1600-18000 C; cool rapidly to 12500C, then slowly thereafter

Results: Cloudy material becomes clear. This can be used in combination with any process except Process 2.

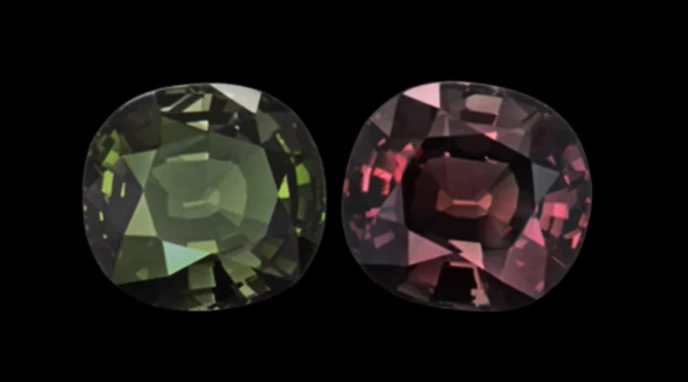

Figure 1. Removal of silk from geuda stones before and after heat treatment.

B. Process No. 2: Development of silk

Treatment conditions: Heat to approximately 1100-14000C for 1-14 days or more.

Results: This allows the development of a star in Titanium-rich material. It can be used with any process except process 1. However, this is generally only possible in synthetic corundum where Titanium content is much higher than natural gems.

Figure 2.Synthetic Star Rubies (Development of silk).

C. Process No. 3: Development of blue colour

Treatment conditions: Heat to between 1600-19000C in a reducing atmosphere.

Results: In this treatment Geuda sapphire (Sri Lanka, Madagascar or elsewhere), Kashmir sapphire etc., can be used in combination with process 1. Pale silky stones become clear and deep blue. (Note: A small percentage of Sri Lankan stone turn blue when heated in an oxidizing atmosphere)

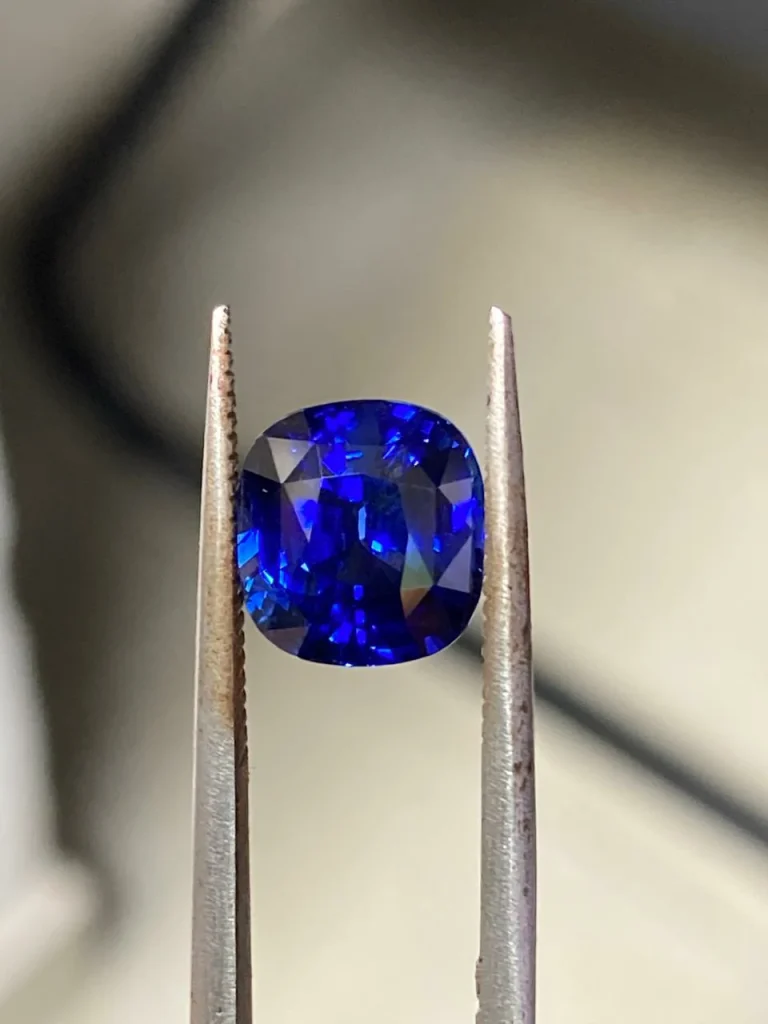

Figure 3.Heat treated blue sapphires.

D. Process No. 4: Removal of blue colour

Treatment conditions: Heat between 800-19000C (may be as low as 4500C) inan oxidizing atmosphere.

Results: While in theory, it is possible to lighten the colour of dark, “inky” blue Australian, Thai, Cambodian and Nigerian sapphires, the effect is mainly removal of silk, thus increasing transparency. Higher temperatures may be used in combination with Process 1. (Note: A reducing atmosphere has also been reported for this type of heating.)

Removal of the blue component from purplish Thai, Cambodian, Burmese, Sri Lankan, Kenyan and Tanzanian rubies can be done. Higher temperatures may be used for Burmese, Sri Lankan and East African rubies in combination with process 1. Blue cores of Mong Hsu (Burma) rubies can also be removed in this way.

Removal of the blue component from green or greenish yellow Australian and Montana sapphires can be done in this method thus intensifying the yellow colour. This is rarely effective.

Figure 4. Heat treated pink sapphires (Blue component removed after heat treatment)

E. Process No.5: Development of yellow colour

Treatment conditions: Heat to between 1600-19000C in an oxidizing atmosphere.

Results: White and pale yellow Sri Lankan sapphires become intense yellow or gold colour. Pink stones change to an orange colour or Padparadscha colour.

Figure 5.Heat treated yellow sapphires

F. Process No. 6: Surface (bulk/volume) diffusion for development of colour/star

Treatment conditions: Heat between 1600-17500C with the gems packed in slurry of Titanium (Ti) and Ferrous (Fe) or Cromium (Cr) oxides.

Results: Pale gems develop a thin colour layer at and just beneath the surface (0.10-0.50 mm deep).

Figure 6.Diffused blue sapphires

G. Process No. 7: Fracture filling

Treatment conditions: Heat between 1300-19000C (depending on flux used) with the gem packed in a suitable fluxing agent (such as borax), for 10-20 hours.

Results: This can be performed on any fractured gem and will result in filling of the fractures, making them less refractive (and so less visible). The gem is also stronger as a result.

Figure 7. Glass filled rubies

H. Process No. 8: Beryllium (Bulk/lattice) diffusion

Treatment conditions: Heat to 1700-18000C with gems buried in a dry powder of Al2O3 containing 4% powdered chrysoberyl or 0.8% BeO.

Results: White sapphires become yellow sapphires. Pink sapphires become Padparadscha.